Connected Construction

Caterpillar Equipment Asset Monitoring for Automated Job Cost & Predictive Maintenance.

Improving Construction Companies Bottom Line by connecting Caterpillar Equipments to the ERP using IoT and Machine Learning

Digital Twinning and Job Cost

Create digital twins of all the construction assets by ingesting the data from VisionLink into Oracle IoT Asset Monitoring and then update the Meter Readings against the Job Cost for cost accounting against the project the equipment is assigned to.

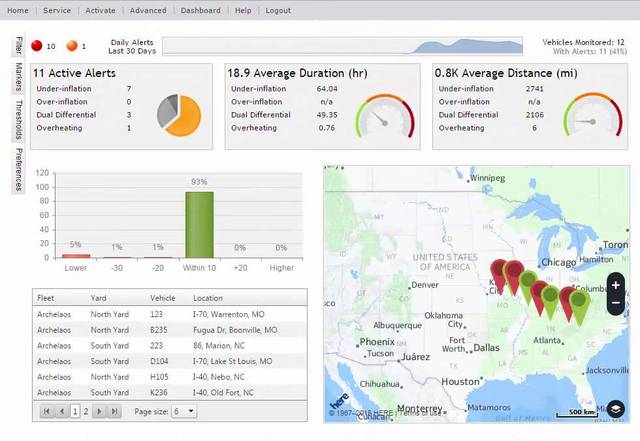

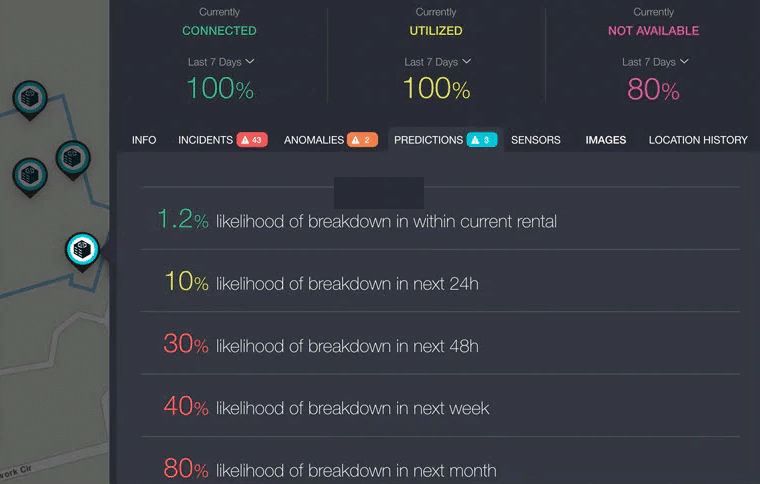

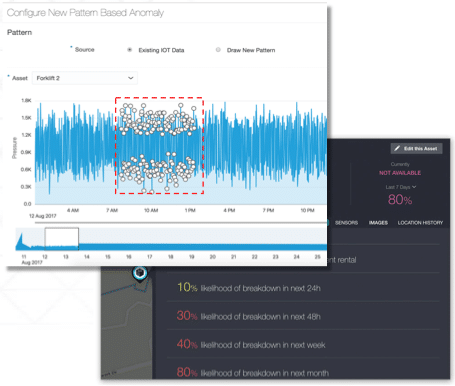

Predictive Actionable Insights

Use Oracle IoT Asset Monitoring and its embedded Machine Learning Model based on ingested AEMP data from VisionLink to predict potential down-time of the Caterpillar equipment for predictive maintenance.

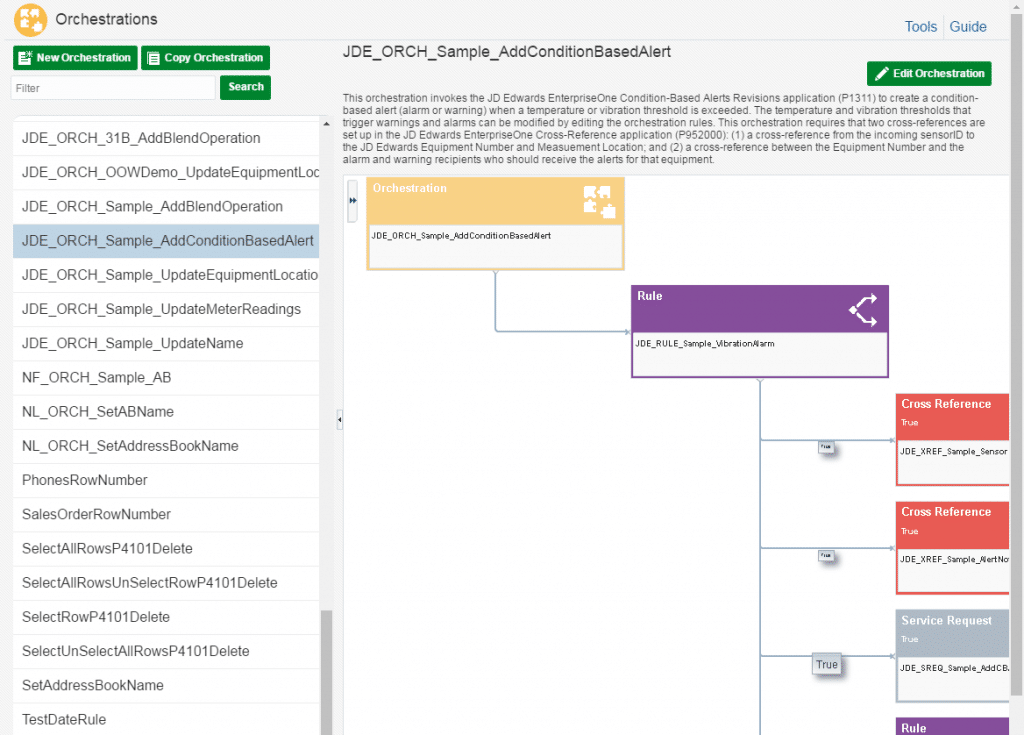

Digital Threads

Create proactive Service Work Orders in conjunction with the maintenance policies defined in JD Edwards Capital Asset Management module.

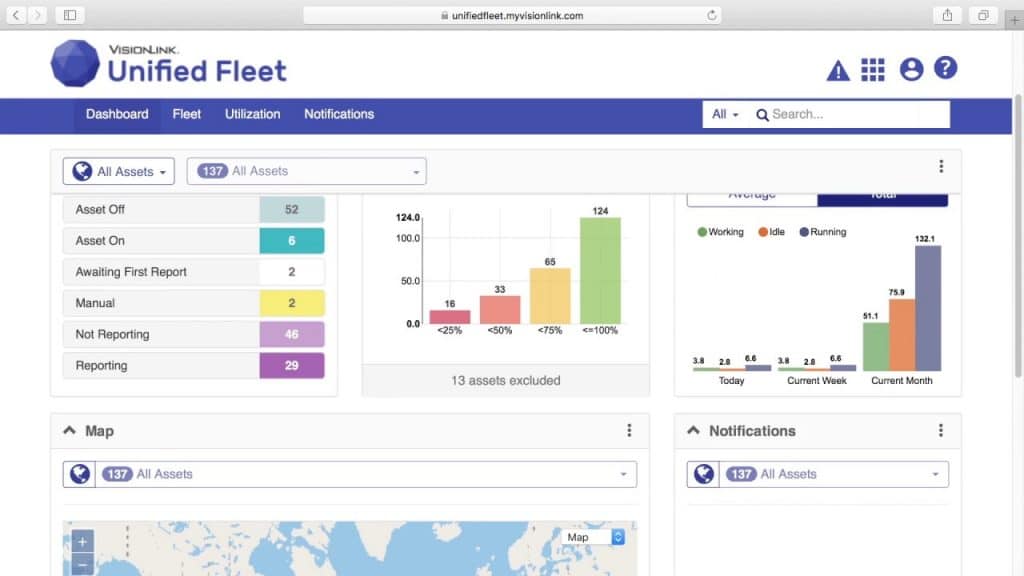

Digital Twins using Caterpillar’s VisionLink

Using the geofencing capabilities, the assets allocated to certain project sites are grouped against the specific projects (job costs). Mirroring the real-time location, fuel usage, mileage, and other operational parameters, the digital twins created in VisionLink truly map the physical and operational state of the caterpillar equipment on the project site.

Features